I am delighted to announce that we have just installed a brand new goniophotometer in our testing laboratory!

The GO-2000 Goniophotometer is an exciting addition to our already extensive laboratory facilities and opens up our testing and manufacturing capabilities even further.

The GO-2000 is faster and even more accurate than its predecessor. It also increases the scope of products that we can test in-house, including LED luminaires and street lighting. Previously, our testing range was fixed to increments of 5° elevation and 15° azimuth. We are now able to test to 0.5° elevation and 5° azimuth!

It didn’t look that heavy in the pictures . . .

It didn’t look that heavy in the pictures . . .

The GO-2000 is a substantial piece of equipment which weighs in excess of 400 kilos. The base is, by far and away, the heaviest component since it needs to not just hold and rotate the rest of the photometer and the luminaire being tested but also to do so with great precision.

Since the laboratories here at Jordan are situated on the first floor, installation proved to be something of a challenge. It didn’t, however, take us long to come up with an innovative solution! A fork lift truck was employed to lift 12 crates of component parts onto a mezzanine floor. Then, engine hoists moved these crates towards the laboratory where a ramp was constructed to enable us to get the GO-2000 safely inside.

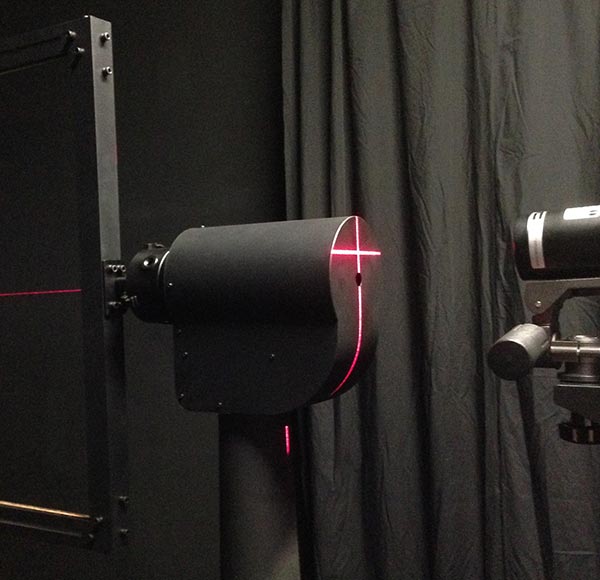

Talking of precision, the goniophotometer is equipped with not one but two lasers! The first, fixed, laser is used to centre the luminaire on the rig. The second laser is used to align the photocell with the goniophotometer.

Enhanced test results

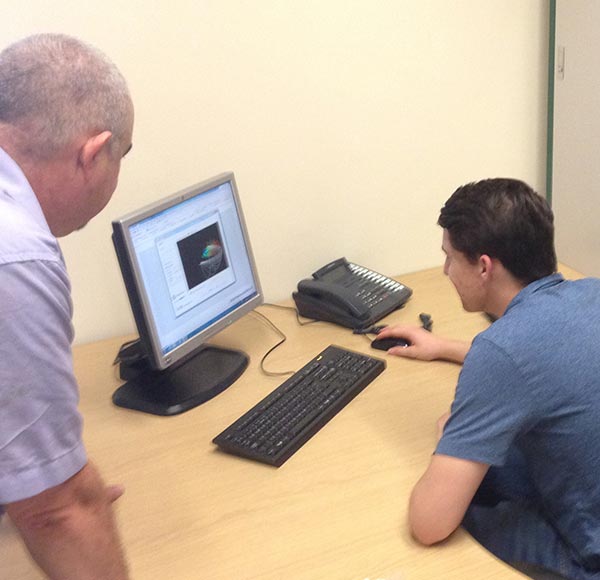

The software driving the GO-2000 gives faster scan times (typically half an hour) and enables the polar curve to be viewed in real time as it is being built up. We are now also able to measure lumen outputs direct from the photometer rig.

The software driving the GO-2000 gives faster scan times (typically half an hour) and enables the polar curve to be viewed in real time as it is being built up. We are now also able to measure lumen outputs direct from the photometer rig.

Full details of the GO-2000 goniophotometer can be found HERE.

[threecol_one]

Installation

[/threecol_one] [threecol_one]

Controls

[/threecol_one] [threecol_one_last]

Laser precision

[/threecol_one_last]